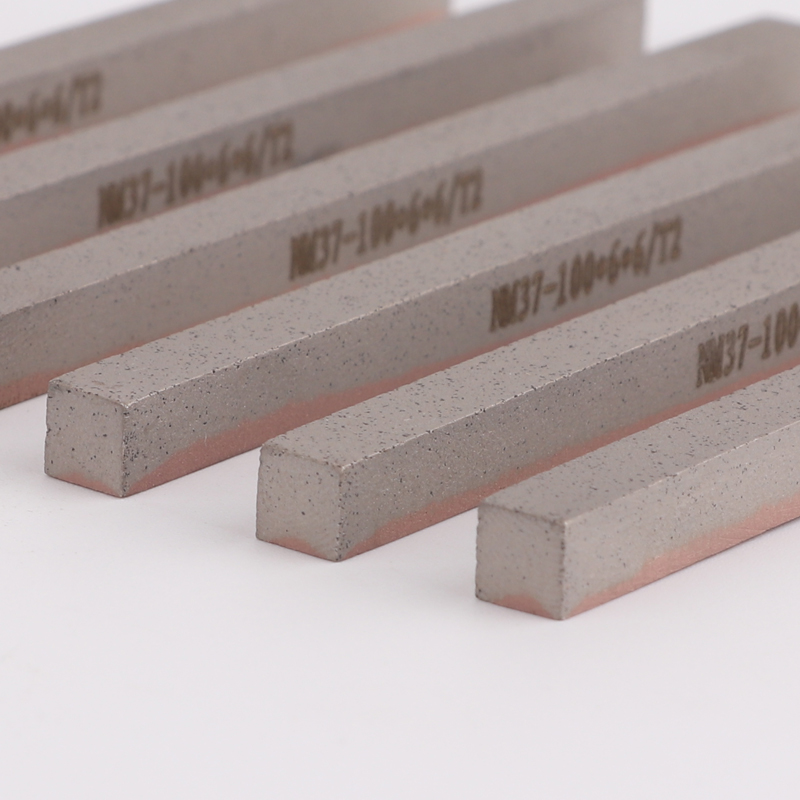

• High quality of diamond and CBN abrasives from USA.

• Bond Type: Metal Bond.

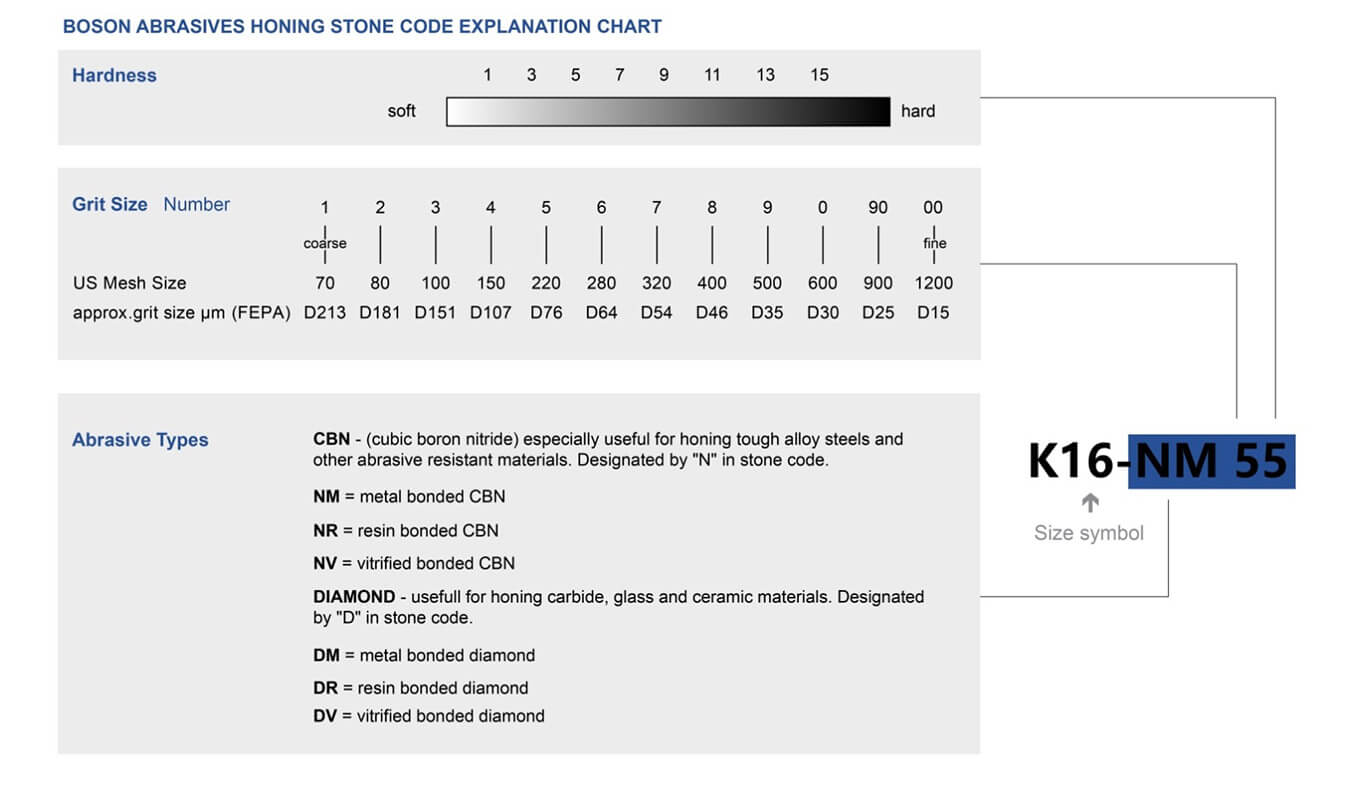

• Grit Size : D251 to D15 (diamond mesh size 60/80 ~ 2000).

• Improved Honing for all types of materials.

• High Material Removal Rate.

• Optimum Performance and Consistant Quality.

Diamond and CBN (cubic boron nitride, Borazon) honing stones are widely used in modern production processes. Numerous factors determine the honing result. The ideal composition of honing stone and all other influencing factors to the honing process need to be coordinated in order to achieve optimal results. High production quality, short cycle times and longevity of the tools are achieved this way.

With extensive honing expertise, our seasoned technicians tailor the perfect honing stones for your specific application. We will define the most suitable abrasives and bond system according to the hone component material, allowances, surface quality.

In principle, the perfect honing stone consist of three different main components, which offer the required cutting.

Abrasive

The abrasive is the most important component of each honing stone. Synthetic diamonds or cubic boron nitride (CBN) in various grit sizes are used.

Bond

The second component is the metal bonding which is responsible for the proper adhesion of the abrasive crystals warranting excellent wear performance.

Steel Blank or Carrier

The copper-plated steel blank is the third and last component and is the support material of each honing stone in a drawn, galvanized form.

The abrasive and the bond are weighed, mixed and proportioned according to exactly define operation plans. The premixed portions are then filled into prepared sintering molds and fitted with the appropriate steel blanks. After this, all three elements are sintered under high temperature. During the sintering process and abrasive layer develops.

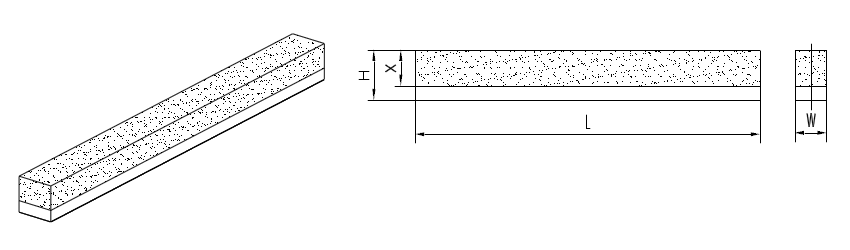

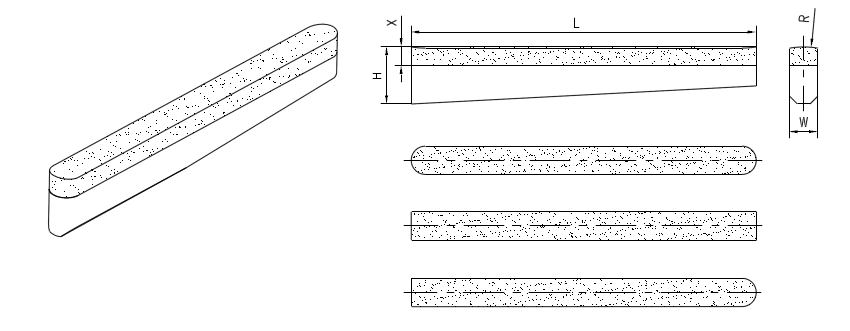

Standard honing stone

The abrasive layer with a steel blank, the honing stone is soldered or bonded onto the stone holder of the tool.

How to order: L x W x H x Y

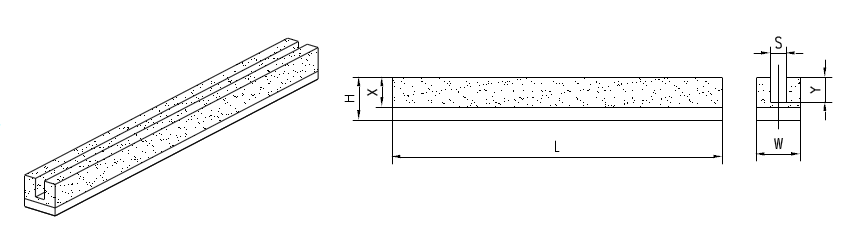

Slotted standard honing stone

The same structure as the standard honing stone but with a longitudinally slotted abrasives for better cooling and chip removal.

How to order: L x W x H x Y x S

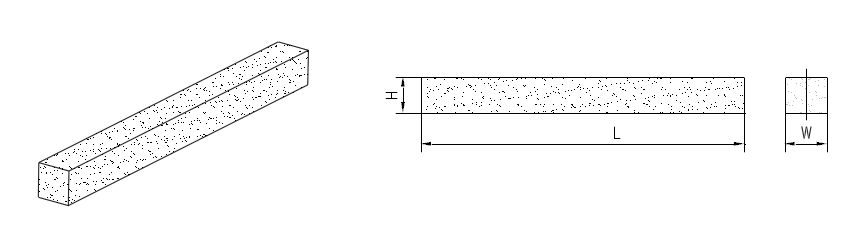

Solid honing stone

Consist only of an abrasive layer without a steel blank and is also soldered or bonded onto the stone holder of the tool.

How to order: L x W x H

Compact honing stone

A ready to be installed stone for direct use on the tool body. This type of stone is use in tool systems for machining high precision bores. In general, both end with rounded angular.

How to order: L x W x H x Y

Stone drawing required.

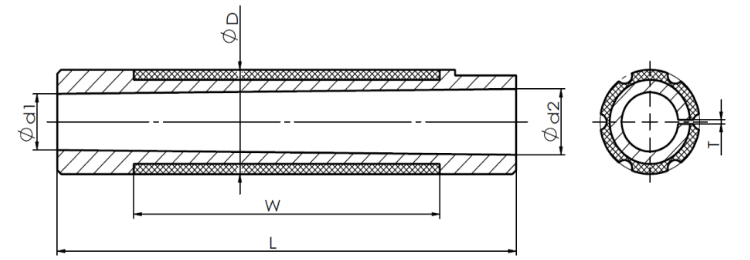

Honing sleeve

Direct fit on honing tools expansion by cone rod for progressive honing.

How to order: L x W x D x d1 x d2

Stone drawing required.

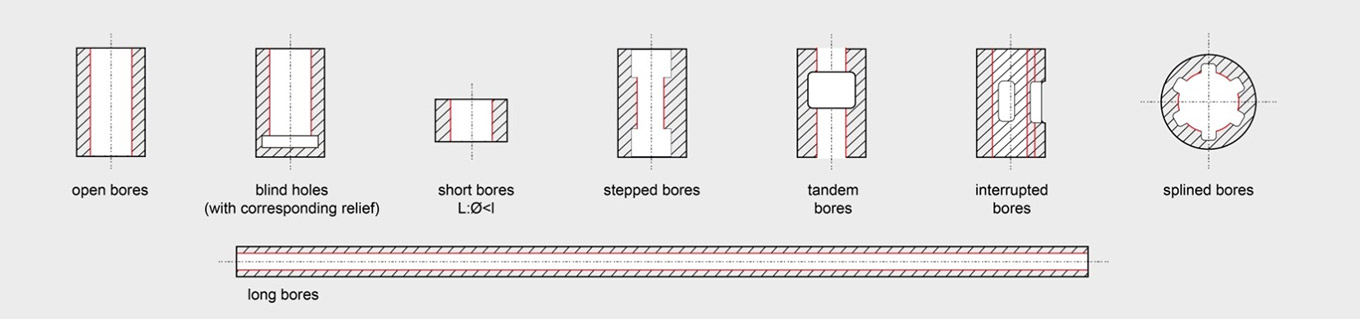

Bore types:

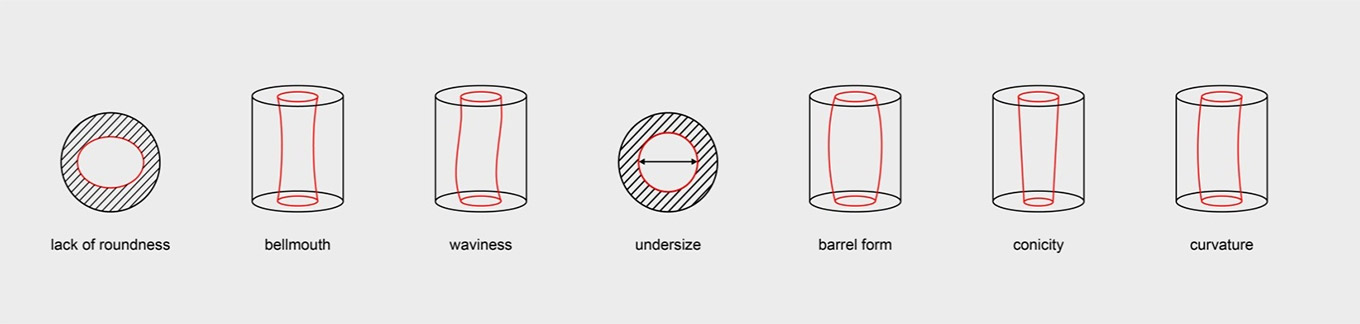

The following bore errors can be correct by honing:

Please send us your questions or inquiries via the form below and we will get back to you within 24 hours.